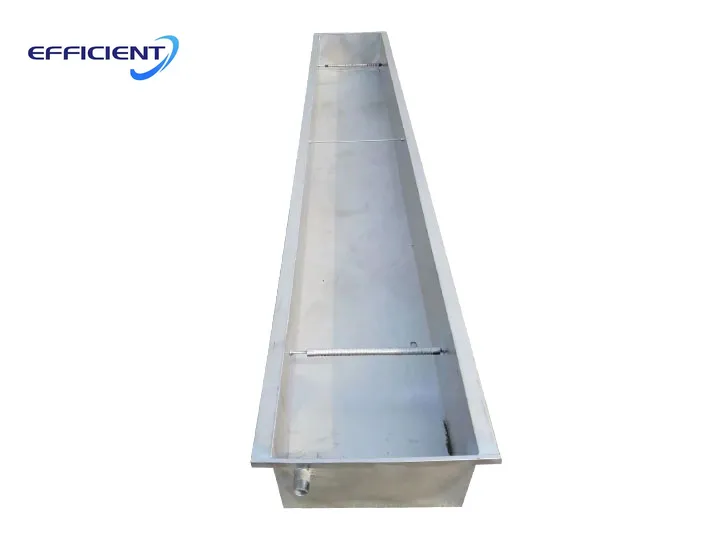

Cooling Tank for plastic recycling is made of stainless steel and is filled with cold water to help ensure that the plastic strip cools down while allowing the plastic to harden quickly for subsequent cutting. This is one of the most important pieces of equipment in a plastic recycling line.

Introduction of Plastic Cooling Tank

The plastic strips extruded by the plastic pelletizer are very hot and soft at the same time when they are first produced. The cooling water tanks rapidly cool down and solidify the strips by means of an effective cooling effect. This ensures that the plastic strip retains its shape and facilitates the subsequent cutting process.

The cooling tank for plastic recycling is equipped with an internal system for connecting water pipes. When the water temperature rises, the system can automatically circulate and replace the water to ensure that the water temperature is always within the appropriate range. This effectively guarantees the continuity and stability of plastic pellet production.

Cooling Tank for Plastics Recycling Application

The specifications of the cooling water tank are perfectly matched to the plastic pelletizer. The cooling water tank is usually connected with the plastic pelletizing equipment, pellet cutting machine, Our recycling line has a capacity of 200kg/kg to 2000kg/h, realizing the integrated operation of the whole plastic granule production line.

Our recycling line has been sent to Kenya, Saudi Arabia, Nigeria and other Togo countries and regions, and the plastic pellets produced have been well received by customers.