Welcome to Efficient, a leading manufacturer of advanced recycling equipment. Our EPE EPS Foam Granulating Line is a state-of-the-art solution designed to efficiently process waste EPE and EPS foam materials. This granulating line incorporates various styrofoam recycling machines that work seamlessly together to transform foam waste into high-quality plastic pellets, reducing environmental impact and maximizing resource utilization.

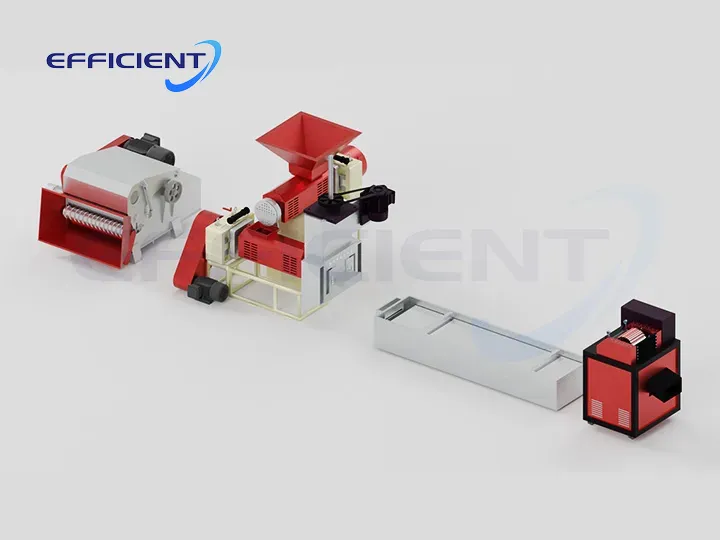

3D Display of Styrofoam Recycling Machine

Styrofoam Recycling Machine Specifications

EPS Foam Melting Machine

| Size | Feeding Port Size | Motor | Heating Power | Output |

|---|---|---|---|---|

| 1500*800*1450mm | 450*600mm | 15kw | 3kw | 100-150kg/h |

The EPS foam melting machine is the first step in the granulating line. It efficiently melts and decompresses the EPS foam, preparing it for further processing.

EPE Foam Pellet Making Machine

| Model | Machine Size | Inlet Size | Power | Capacity | Heating Method |

|---|---|---|---|---|---|

| SL-160 | 3400*2100*1600mm | 780*780mm | 30kw | 150-200kg/hour | Heating Ring |

The EPE foam pellet making machine transforms the melted foam into small pellets, ensuring uniformity and quality in the final product.

Vertical Foam Compactor Machine

| Model | Dimensions | Inlet Size | Power | Capacity |

|---|---|---|---|---|

| SL-300 | 3000*1400*1400mm | 1100*800mm | 11kw | 150kg/h |

| SL-400 | 4600*1600*1600mm | 1200*1000mm | 22kw | 250kg/h |

The vertical foam compactor machine further compresses the foam pellets, reducing their volume and facilitating storage and transportation.

Horizontal Foam Densifier

| Model | Dimensions | Inlet Size | Power | Capacity |

|---|---|---|---|---|

| SL-300 | 3000*1700*900mm | 830*760mm | 15kw | 175kg/h |

| SL-400 | 4600*2800*1200mm | 870*860mm | 22kw | 300kg/h |

The horizontal foam densifier further densifies the foam material, increasing its efficiency and reducing storage requirements.

Raw Materials and Environmental Impact

The EPE EPS Foam Granulating Line is specifically designed to process waste EPE foam and waste EPS foam. These materials are commonly found in various everyday items such as packaging materials, insulation products, and disposable food containers. However, their improper disposal can lead to significant environmental hazards, including pollution, landfill overcrowding, and non-biodegradability.

Product Operation and Final Output

The EPE EPS Foam Granulating Line works on the principle of converting waste foam into plastic pellets. The process begins with the EPS foam melting machine, which melts and decompresses the foam material. The melted foam is then transformed into small pellets by the EPE foam pellet making machine. These pellets are further compressed and densified by the vertical foam compactor machine and horizontal foam densifier, respectively. Finally, the granulating line produces high-quality plastic pellets that can be used in various applications.

Frequently Asked Questions

1. Can the EPE EPS Foam Granulating Line handle different types and sizes of foam waste?

Yes, the EPE EPS Foam Granulating Line is designed to process various types and sizes of foam waste, including EPE foam and EPS foam. Whether it’s packaging materials, insulation products, or disposable food containers, the granulating line can efficiently handle them.

2. What is the output capacity of the granulating line?

The output capacity of the granulating line depends on the specific models of the machines used. Our machines offer a wide range of capacities, ranging from 100kg/h to 300kg/h, allowing you to choose the capacity that suits your production needs.

3. Are the plastic pellets produced by the granulating line of high quality?

Yes, the granulating line is designed to produce high-quality plastic pellets. The process ensures uniformity and consistency in the size and density of the pellets, making them suitable for various applications in industries such as packaging, construction, and automotive.

4. What are the maintenance requirements for the granulating line?

The granulating line is designed for durability and ease of maintenance. Regular cleaning and maintenance, as outlined in the user manual, are necessary to ensure optimal performance and longevity of the machines. Our technical support team can provide guidance on maintenance procedures.

5. Is technical support available after purchasing the granulating line?

Absolutely. We provide comprehensive technical support to our customers. Our team of experts is available to assist you with installation, training, troubleshooting, and any other technical queries or concerns you may have. We are committed to ensuring your success with our equipment.