High-Density Polyethylene (HDPE) is one of the most valuable and commonly recycled plastics. Sourced from items like milk jugs, shampoo bottles, and industrial barrels, clean HDPE regrind is in high demand. However, turning abrasive flakes into high-quality pellets requires more than just a standard machine; it requires a purpose-built HDPE granulator.

The question of how to pelletize HDPE flakes successfully comes down to understanding the material’s unique properties and choosing equipment designed to handle them. This guide covers the key considerations in the HDPE granulation process to ensure high efficiency and profitability.

Key Requirement 1: High Torque for Pelletizing Rigid Plastic

Unlike soft, fluffy film, HDPE flakes are rigid, dense, and have a high melt flow index. This means the machine’s screw requires significantly more force to convey, compress, and plasticize the material without stalling.

- The Solution: A High-Torque Granulator for HDPE A machine’s ability to handle this is determined by its drivetrain. The combination of a powerful main motor and a hard-gear reducer (as specified in our models) delivers the high torque necessary to process rigid plastics consistently. A standard HDPE flakes pelletizer with an inadequate gearbox will struggle, leading to motor overload and production stops.

Key Requirement 2: Durability Against Abrasive Material

HDPE flakes, especially after being crushed, have sharp, abrasive edges. Over time, these flakes can cause significant wear on the most critical components of the machine: the screw and barrel. Premature wear leads to poor melt quality and costly replacements.

- The Solution: A Wear-Resistant Screw for Rigid Plastic The material science of the screw is paramount. A single screw extruder for HDPE should be constructed from hardened, high-performance steel. Our screws and barrels are made from 38CrMoAl alloy steel and then undergo a nitriding treatment. This creates an extremely hard surface that withstands the abrasive nature of HDPE, ensuring a much longer service life and consistent performance. While a two-stage extruder for HDPE can be used for extra filtration, a robust single-stage HDPE flakes pelletizer built with these durable materials is often sufficient for clean HDPE regrind.

Choosing the Right HDPE flakes pelletizer for Your Production Scale

Matching the machine’s capacity to your operational volume is a critical business decision. The HDPE recycling process is scalable, and the right machine will align with your feedstock supply and sales goals. The table below details our full range of machines suitable for an HDPE pellet production line.

For example, a business processing a few tons per day might select a 300kg/h HDPE pelletizer like our Type 150. A large industrial facility would require the power and throughput of a 420kg/h HDPE granulator like the Type 220 to maximize production. Explore our full range of plastic granulators to find the perfect fit.

Maximizing Your HDPE Recycling Profitability

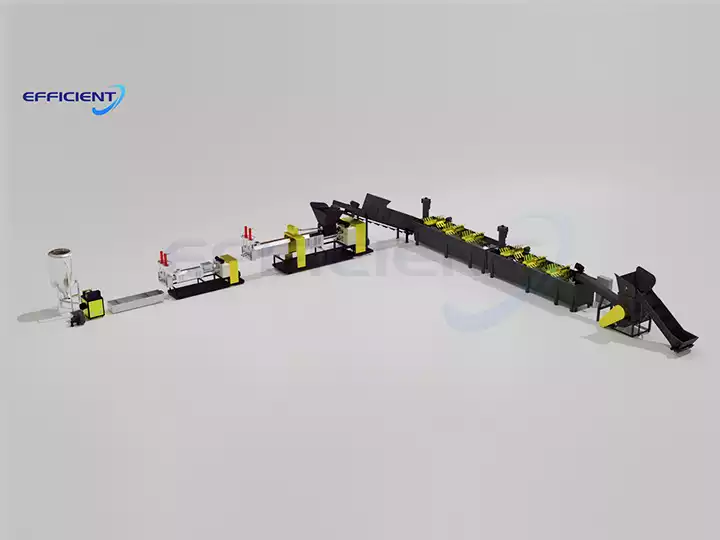

The market price for recycled HDPE pellets is consistently strong, making it a lucrative sector. Success depends on producing clean, uniform pellets efficiently. This starts with a proper pre-processing line, including a shredder and washing tank, which can be integrated into a complete rigid plastic recycling line.

By investing in a powerful and durable HDPE flakes pelletizer that is correctly sized for your operation, you ensure minimal downtime, low maintenance costs, and a high-quality final product, which are the cornerstones of a profitable recycling business.

Ready to turn your HDPE scrap into a high-profit product? Explore the technical details of our granulators engineered for rigid plastics.