Our Plastic Film Washing and Pelletizing Line is a comprehensive solution for recycling waste films, such as PP woven bags, packing bags, LDPE LLPE bags, and PP jumbo bags. etc. With our innovative plastic film recycling machines, the waste films will be crushed and cleaned thoroughly and you will obtain high-quality recycled plastic pellets in the last recycling step.

The standard capacity of the plastic film washing line is 100-500kg/h for most plastic recycling factory. Shuliy Group also offers larger output for customized demands.

Applicable Materials of Recycling Line

- Recycle type: HDPE/LDPE/LLDPE/PP/PVC

- Application: post-industrial recycling, post-consumer recycling

- Recycle Material: film on rolls, defective film and bag products, plastic printed zipper bags, defective PP LDPE film and bag production waste, HDPE soft irrigation pipe, edge trim, bag scrap, laminated film for food packing, multilayered film, plastic flexible packaging materials, bubble wrap, laminated plastic woven bags, woven sacks, PP rope, jumbo bags, T-shirt bag cut-off, leno bags, PP raffia bags, etc.

Recycled HDPE/LDPE/LLDPE/PP Granules You Will Obtain

The final products are plastic granules, they can be made into a variety of colors with smooth surfaces. The granules are not easy to break, they are of reliable stability, uniform size and density.

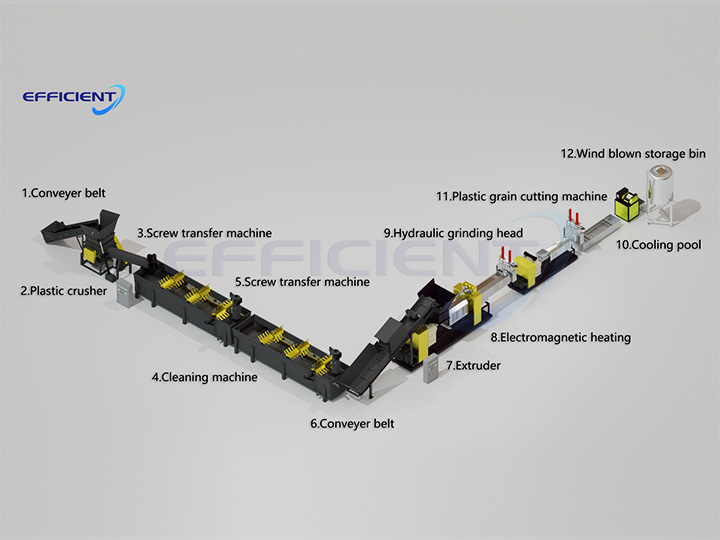

Know More about the Plastic Film Recycling Process

Step 1: LLDPE/LDPE/HDPE/PP film crushing and washing

Firstly, the plastic film is fed into a plastic shredder where the film can be shredded into pieces without interruption. Next, the shredded film flakes will be washed by a rinsing tank machine. A large amount of contaminants are discharged. This step effectively removes contaminants such as sand, sludge, labels and grease from PP/PE films.

Step 2: Washed film flakes lifting and drying

Secondly, the cleaned plastic film is quickly dried by centrifugal force in a vertical lifting dewatering machine and then lifted out of the washing tank into a silo for storage.

Step 3: LLDPE/LDPE/HDPE/PP film melting and pelletizing

Next, by an automatic conveyor, the plastic film material is transported to the plastic pelletizer machine, where the high temperature melts the film and extrudes it through the die. The extruded plastic strips are cooled down and hardened by passing them through cold water.

Step 4: Extrusion & Strand pelletizing

In the final step, a pellet cutter device cuts the plastic strips into small pellets with adjustable cutting speed and size.

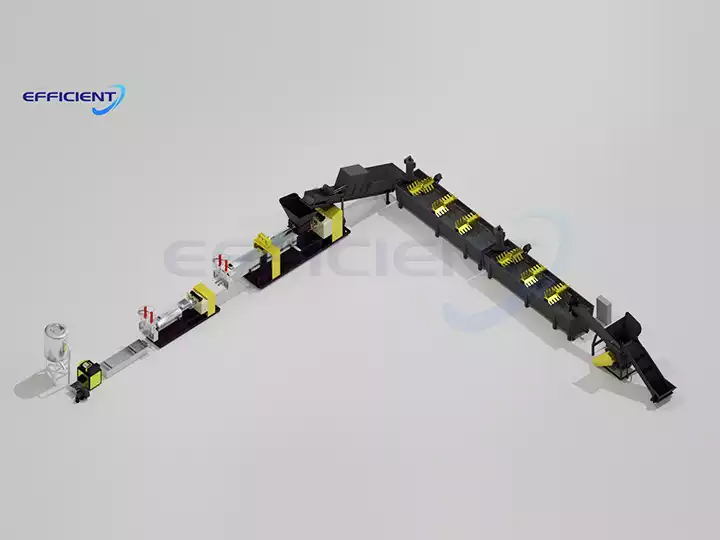

3D Display of Plastic Film Washing and Pelletizing Line

FAQ of Plastic Film Recycling Machine

Do the PP/PE film recycling machines work efficiently?

Our machine is of high-capacity, the output is 100-500Kg/h, capable of handling a large amount of waste plastics, can quickly complete the crushing, cleaning and granulating. The machine can work continuously for 24 hours.

How much does a plastic recycling machine cost?

The price of our plastic recycling machine for sale depends on its model, capacity and functions. Gernerally, The price of film recycling line is usually in the range of US$10,000-30,000/set, and the single machine is around several thousand dollars. Please contact us for specific price.

How to install the complete plastic film recycling line?

We provide online guidance, if you purchase a large number of machines or production lines, we arrange for engineers to travel to your country to assist you with on-site installation, test runs and provide worker training to ensure that your plastics recycling program is on schedule.

How long does your machine last and how to repair it?

Our plastic recycling machines can work at least for ten years. When you ordered our equipment, it means you ordered our services too. The machine will not break under standardized operation. But the recycling machine will inevitably need maintenance after a long time. The sales manager will continue to follow up the use of your machine, if there is any problem with the machine, you can contact him at any time, we provide lifelong machine repair and maintenance services.

My region has a strict environmental policy, will your machine pollute the environment when working?

It will generate smoke when the plastic film with too much water. Therefore we can provide an extra dewatering machine for you to remove water much better. In addition, we also provide professional smoke removal equipment.

What countries do you export your machines to?

We have shipped our recycling machines to Congo, Ethiopia, Nigeria, Kenya, Iran, Sudan, Tanzania, Oman, Saudi Arabia, America, etc. After they started to used the machines, we always received pleasant feedback videos and pictures taken by our global clients.

Who Bought Our Plastic Film Recycling Machines?

Saudi Arabia HDPE Film Recycling Plant

- Application: post-consumer recycling

- Reycling capacity: 1000kg/h

- Recycle material: waste HDPE bags and films

- Installation: On-site guided installation + worker training

- Delivery time: 20 days

Related video: Saudi Arabian plastic recycling plant

Know more: case 1

LDPE Film Pelletizing Plant Installed in Nigeria

- Application: post-consumer recycling

- Production output: 500kg/h

- Recycle material: LDPE films and bags from domestic waste

- Installation: On-site guided installation and inhouse training

Related video: Plastic recycling factory installed in Nigeria

Know more: case 2

Plastic Bag Granulating Plant in Kenya

- Application: post-industrial recycling

- Recycling capacity: 200kg/h

- Recycle material: HDPE/PP films and bags

- Installation: Online guided installation

Watch video: HDPE Granule Production Line in Kenya

Know more: Case 3

Summary

In summary, Shuliy’s Plastic Film Washing and Pelletizing Line is an advanced recycling solution designed to transform waste plastic films and bags into high-quality recycled plastic pellets. By incorporating efficient plastic recycling machinery and a systematic process, our plastic film washing line enables businesses to contribute to a sustainable future while reaping the economic benefits of recycled materials.

Contact us today to learn more about our innovative recycling machines.