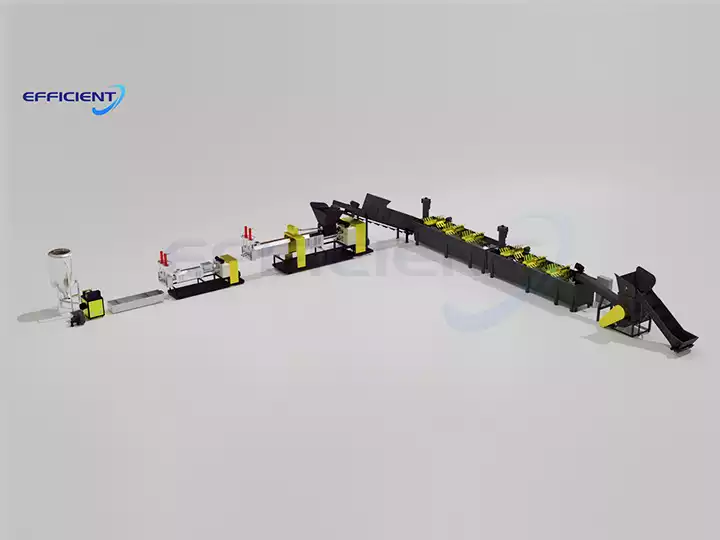

The Plastic Granulating Line is a great solution designed to recycle and transform various hard plastic materials like HDPE PP into high-quality granules. The capacity of our plastic granule production line is 100-500kg/h.

This advanced plastic recycling line comprises four essential machines, each playing a crucial role in the process: the Plastic Crusher Machine, Plastic Rinsing Tank, Plastic Horizontal Dewatering Machine, and Plastic Pelletizing Extruder. Let’s explore these recycling machines in detail, along with their specifications and benefits.

What Is The Hard Plastic Recycling Process?

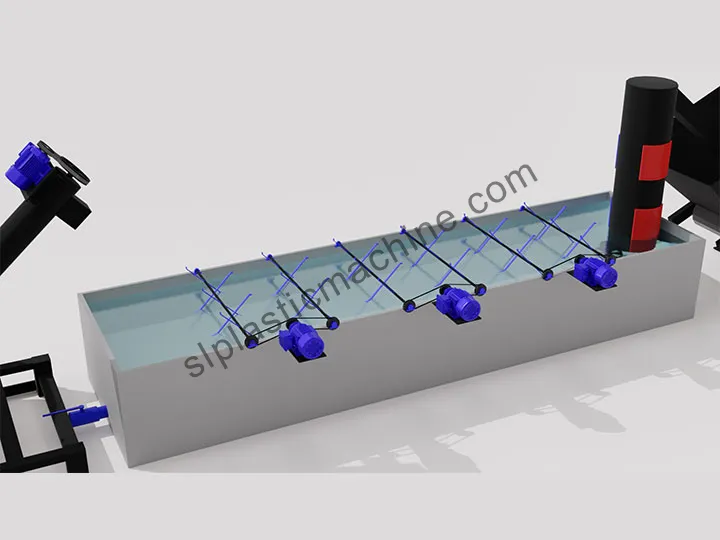

Step 1: Washing and Crushing

Crushing always is the first step for hard plastic recycling. Put the rigid materials like rigid containers in a plastic shredder, the shredded plastic flakes (regrinds) need to be washed in a washing tank. The washing tank can remove the dirt and grease from the plastic flakes. Our superior-quality Plastic Rinsing Tank, model SL-150, boasts a tank length of 15-20m. With ten rotating wheels spaced at a distance of 1.5-2m, this tank provides effective cleaning and rinsing of plastic flakes.

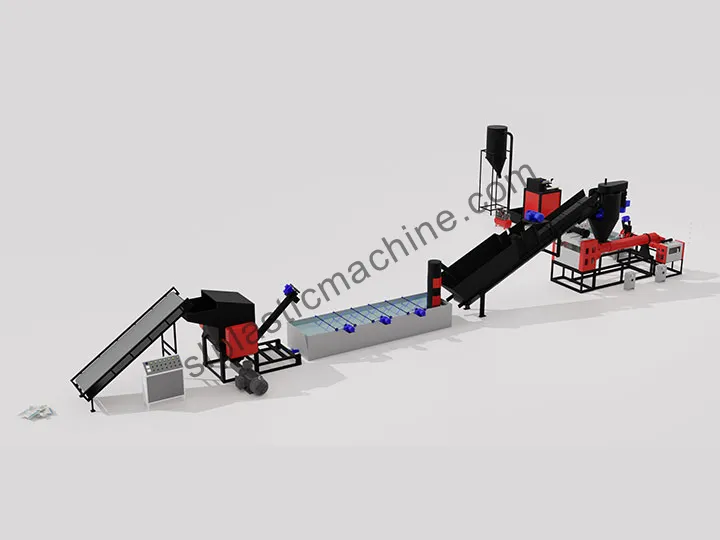

Step 2: Drying

The drying of the plastic chips is done so that the pelletising process can be done with less fumes and at a guaranteed temperature. We match the recycling line with both vertical and horizontal dryers. The dryers use centrifugal force to shake out the moisture, ensuring that the plastic regrinds have less than 5 percent moisture.

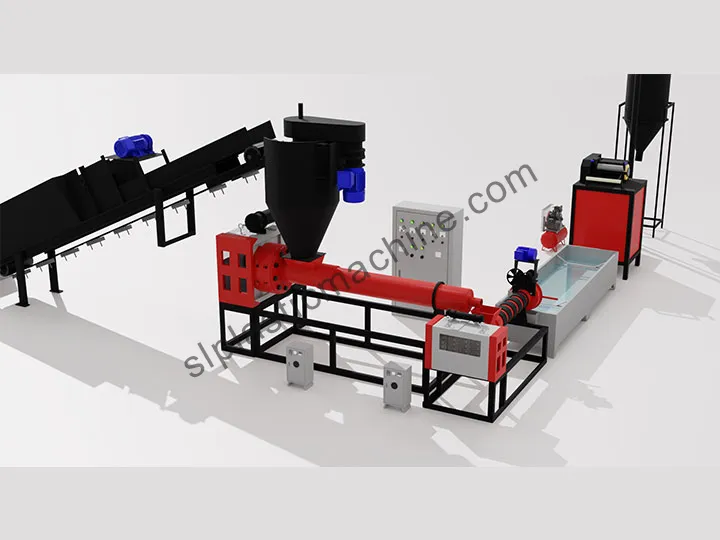

Step 3: Pelletizing and Cutting

After drying, the raw material will be fed into the plastic pelletizer, where the plastic will be gradually melted at a temperature of 300 degrees Celsius. Different materials require slightly different melting temperatures. The plastic melt is extruded by a screw, cooled by cold water and cut into small pellets by a pellet cutter device.

Raw Materials of Plastic Pelletizing Line

The plastic pelletizing line is designed for hard plastic recycling, such as shredded plastic regrinds, PP and HDPE barrels, food packaging boxes, wire and cable, construction materials, injection moulded items, chemical drums, blue HDPE jerry cans, plastic pallets, electric kwh meters, automotive bumpers and so on.

Final Product of Plastic Granulating Line

The Plastic Granulating Line produces recycled plastic pellets that possess excellent quality and consistency. These pellets can be used in various industries, including packaging, manufacturing, and construction. They serve as a sustainable alternative to virgin plastic materials, reducing the dependence on limited natural resources and contributing to a greener and more circular economy.

FAQs Plastic Flake Pelletizing Line

Q: What types of plastic waste can be processed by the plastic flake pelletizing line?

A: The plastic flake pelletizing line is designed to process various hard plastic materials, including PP and PE plastic barrels, food packaging boxes, wire and cable, construction materials, and medical equipment supplies.

Q: What are the advantages of using recycled plastic pellets?

A: Recycled plastic pellets offer several advantages, such as reduced environmental impact, conservation of natural resources, cost-effectiveness, and the ability to meet sustainability goals.

Q: Can the plastic flake pelletizing line handle different plastic types simultaneously?

A: Yes, the plastic flake pelletizing line is capable of processing different types of plastics. However, it is important to ensure compatibility and separate materials with different melting points for optimal results.

Q: What is the maintenance requirement for the Plastic Granulating Line?

A: Regular maintenance, including cleaning, lubrication, and inspection of machine components, is essential to ensure the efficient and reliable operation of the Plastic Granulating Line. Detailed maintenance instructions are provided in the user manual.

Q: Can the Plastic Granulating Line be customized to suit specific production requirements?

A: Yes, Efficient provides customized solutions to meet specific production needs. Our experienced team can work closely with customers to tailor the Plastic Granulating Line accordingly.

Customer Case of Plastic Flake Pelletizing Line

One of our esteemed customers from Kenya embarked on a profitable new venture by purchasing Efficient’s Plastic Granulating Line. Kenian customer recognized the tremendous potential of recycling plastic waste and using recycled plastic pellets to manufacture various plastic products.

With the reliable performance and efficiency of the Plastic Granulating Line, he successfully established a business that not only contributes to a cleaner environment but also generates substantial profits. He took a video of the plastic granulator machine and sent the video to us. He is very satisfied with the machine and have obtained a profit from the plastic pelletizing business.

Conclusion of Plastic Granulating Line

Efficient’s Plastic Granulating Line offers a comprehensive and efficient solution for recycling hard plastic materials. By utilizing advanced machines such as the Plastic Crusher Machine, Plastic Rinsing Tank, Plastic Horizontal Dewatering Machine, and Plastic Pelletizing Extruder, this plastic recycling line ensures the production of high-quality recycled plastic pellets. These pellets can be used as a sustainable alternative in various industries, reducing environmental impact and promoting a circular economy. Choose Efficient for a reliable and eco-friendly plastic recycling solution.